The aviation sector continues to contribute significantly to atmospheric pollution and climate forcing, emitting not only CO2 but also black carbon (soot) and nitrogen oxides (NOx), which are short-lived pollutants that perturb radiative balance, cloud microphysics and human health [1,2]. While Sustainable Aviation Fuels (SAFs) are promoted to decarbonise flight, their overall benefit depends on combustion cleanliness as well as lifecycle carbon. Under realistic operating conditions, SAFs can still generate particulate matter and NOx, and mechanisms remain poorly constrained for emerging fuel formulations [3,4].

This PhD will quantify pollutant formation from representative SAFs and test nanocatalyst strategies to suppress soot and NOx, explicitly linking emitted species to catalyst structure. Using a controlled burner platform with real-time diagnostics, including laser-induced incandescence/fluorescence, multi-species gas analysis and particle image velocimetry, the student will map flame stability, black-carbon emission factors and NOx generation across temperature/mixture regimes [5,6].

Crucially, we will explore national facilities to probe catalyst dynamics under relevant atmospheres. At Diamond Light Source, in situ small-/wide-angle X-ray absorption spectroscopy (SAXS/WAXS) using a gas/heating capillary cell will resolve active-site oxidation state and coordination during lean–rich transients; X-ray absorption spectroscopy (XAS) will quantify nanoparticle size distributions and aggregate restructuring under 300–900 °C profiles; and high-resolution powder diffraction will identify phase transformations following thermal ageing. At Daresbury Laboratory’s SuperSTEM, aberration-corrected scanning transmission electron microscopy (ac-STEM) with spectrum-imaging electron energy loss spectroscopy (EELS), energy dispersive spectroscopy (EDS) and in situ heating will map metal dispersion, support chemistry and carbonaceous deposits at sub-nanometre scales. Together these measurements test catalyst designs suggested to enable cleaner, lower-temperature combustion and mitigate soot formation [7,8].

Environmental significance: by closing the loop between combustion conditions, catalyst structure and emitted species, the project will deliver robust emission factors and mechanistic insight to improve aerosol–chemistry and climate models, and provide evidence to ICAO/CORSIA and related policy frameworks [9,10]. Quantified reductions in soot and NOx also translate to near-term health benefits for communities near major airports [11]. The supervisory team’s complementary expertise in nanomaterials, combustion diagnostics and computational fluid dynamics (CFD), plus co-supervision by facility scientists (DAWN/Athena/Artemis; HyperSpy), ensures the DR can turn advanced measurements into actionable guidance for cleaner aviation.

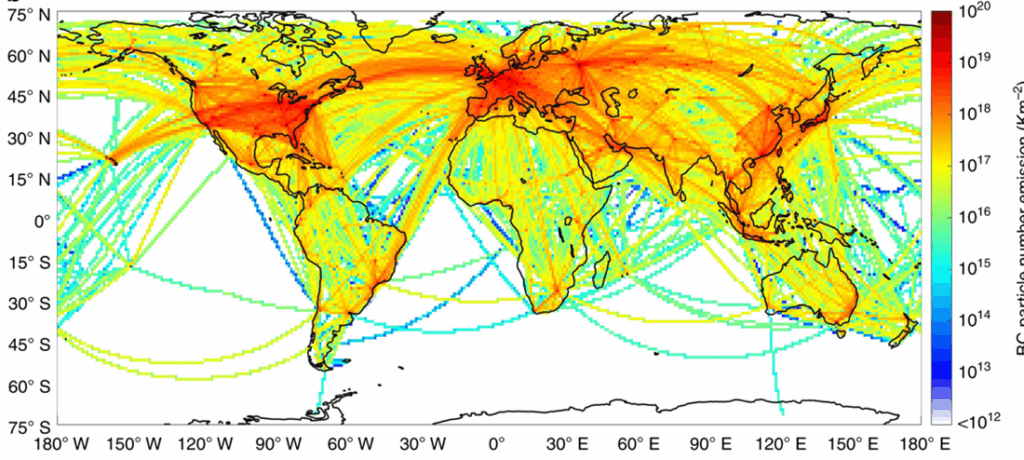

Figure 1: Global distribution of black carbon (BC) particle number emissions from aircraft, highlighting intense emission corridors across the Northern Hemisphere and illustrating aviation’s contribution to atmospheric particle loading relevant to climate and air quality models [11].

This project is not suitable for CASE funding

Each host has a slightly different application process.

Find out how to apply for this studentship.

All applications must include the CENTA application form.

Choose your application route

Nanocatalysts will be synthesised via solution and flame routes, then screened in a controlled burner with laser-induced incandescence/fluorescence, particle image velocimetry, and multi-gas analysis to quantify soot, NOx, CO and unburnt hydrocarbons across equivalence ratio, pressure and temperature. Size/number distributions will be benchmarked with scanning mobility particle sizer (SMPS) and filter-based organic/elemental carbon (OC/EC).

Where results motivate deeper structural insight, we will add targeted, hypothesis-driven facility work (contingent on access): at Diamond Light Source (DLS), in situ SAXS/WAXS with a gas/heating capillary cell to track active-site oxidation/coordination, plus XAS to follow particle growth/restructuring during 300–900 °C ageing; at Daresbury (SuperSTEM), ac-STEM with spectrum-imaging EELS/EDS and in-situ heating to visualise dispersion and carbon deposits below 1 nm. Facility data will complement, not replace, the lab diagnostics and CFD, enabling structure–emissions correlations and design rules.

DRs will be awarded CENTA Training Credits (CTCs) for participation in CENTA-provided and ‘free choice’ external training. One CTC can be earned per 3 hours training, and DRs must accrue 100 CTCs across the three and a half years of their PhD.

The PhD researcher will develop strong interdisciplinary expertise across nanomaterials synthesis, combustion science, and environmental diagnostics. They will receive hands-on training in nanoparticle fabrication, advanced laser diagnostics including laser-induced incandescence (LII), laser-induced fluorescence (LIF), particle image velocimetry (PIV), XAS, and multi-species gas analysis, with additional mentoring in data processing and scientific communication. Through collaboration with both Chemistry and Engineering departments, the student will gain practical skills in experimental design, CFD modelling, and emissions assessment relevant to environmental impact. These core competencies align with future careers in clean energy, aerospace emissions research, and environmental policy, supported by the CENTA training programme and the supervisory team’s cross-sector networks.

We will collaborate with facility scientists at Diamond Light Source (SAXS/WAXS) and Daresbury’s SuperSTEM (ac-STEM-EELS/EDS). Their input will focus on experimental design, safe operation, and data reduction, ensuring facility measurements remain targeted and complementary to our laboratory diagnostics and modelling. Engagement will include pre-experiment consultations, short visits and, where access is granted, co-authored campaigns. No CASE studentship is currently in place; industry interactions will be exploratory and advisory only, aimed at aligning test conditions with sector-relevant operating envelopes.

Year 1 – Synthesis and baseline emissions mapping; validate LII/LIF/PIV, SMPS and gas analytics. Build CFD/chemistry models; pre-register analysis workflows. Scope facility needs; prepare optional DLS (XAS/SAXS/WAXS) and SuperSTEM (STEM-EELS) proposals; complete relevant safety training.

Year 2 – Iterate catalyst formulations using lab diagnostics; quantify structure–emissions response surfaces. If awarded beamtime, run a focused DLS in-situ XAS (with heating/gas cell) and SAXS/WAXS session to test specific hypotheses; analyse the results. Optional SuperSTEM visit for pre/post-exposure imaging and in-situ heating to visualise sintering/encapsulation.

Year 3 – Consolidate lab datasets; uncertainty-bounded emission factors and mechanisms; refine CFD/design rules. Second, smaller facility check, only if needed, to confirm ageing/poisoning mechanisms.

Final 6 months – Thesis writing; manuscript drafting, release open datasets, code and policy-facing summaries.

Candidates can informally contact the supervisors for questions:

To apply to this project:

Applications must be submitted by 23:59 GMT on Wednesday 7th January 2026.